Reducing OPEX and Increasing Customer Satisfaction for Industrial and Commercial Use Power Generators

With GEMBO PRECARE IIoT Platform for OEE and Predictive Maintenance

Abstract

Customers of industrial and commercial use power generators place high expectations on the quality, performance and availability of these systems. They expect them to perform reliably at a moment’s notice when needed, with little or no interruption. The same OEE (overall equipment effectiveness) and predictive maintenance principles used in the manufacturing industry apply to industrial and commercial use power generators. With the GEMBO Precare Platform, power generator OEMs and their service partners can achieve significant reductions in operational expenses and see significant increases in customer satisfaction.

Negative Impacts on OPEX and Customer Satisfaction

Industrial and commercial use power generators are complex systems, which are required to operate reliably without interruption and to be available whenever the need arises for backup power. Like with any complex system any number of things can go wrong and will go wrong, no matter the level of planning and preparation. The challenge is therefore to minimize the financial, operational and psychological cost of any malfunction or suboptimal functioning of the system. The following equipment related events negatively impact operational cost and customer satisfaction:

- Equipment breakdown.

- Equipment downtime, regardless of maintenance, repair, out of fuel or other reasons.

- Reduced power output.

What if you could minimize the probability of any of these events and hence reap the fruits of reduced OpEx and increased customer satisfaction?

The GEMBO PRECARE Solution

GEMBO Precare uses the power of data, analytics and machine learning to mitigate and minimize the impact of equipment related adverse events through the following:

- Predictive maintenance. Avoid costly unscheduled and unnecessary scheduled downtime. Instead determine when precisely to schedule maintenance.

- Catastrophic failure prevention. Avoid costly catastrophic failures, for instance by early detection of abnormal vibrations in rotating parts.

- Maintenance/repair time reduction. Avoid expensive maintenance/repair crew hours with prior knowledge of the kind of maintenance or repair and which spare parts are needed.

- Truck-roll reduction. Avoid unnecessary truck rolls by minimizing planned and unplanned downtime while simultaneously having sufficient information upfront to determine what needs maintenance and/or repair.

- Overall Equipment Effectiveness & customer satisfaction optimization. Maximize OEE and customer satisfaction by eliminating unnecessary and unplanned downtime by keeping any downtime at a minimum and by keeping customer premise equipment running at optimal performance.

Predictive Maintenance

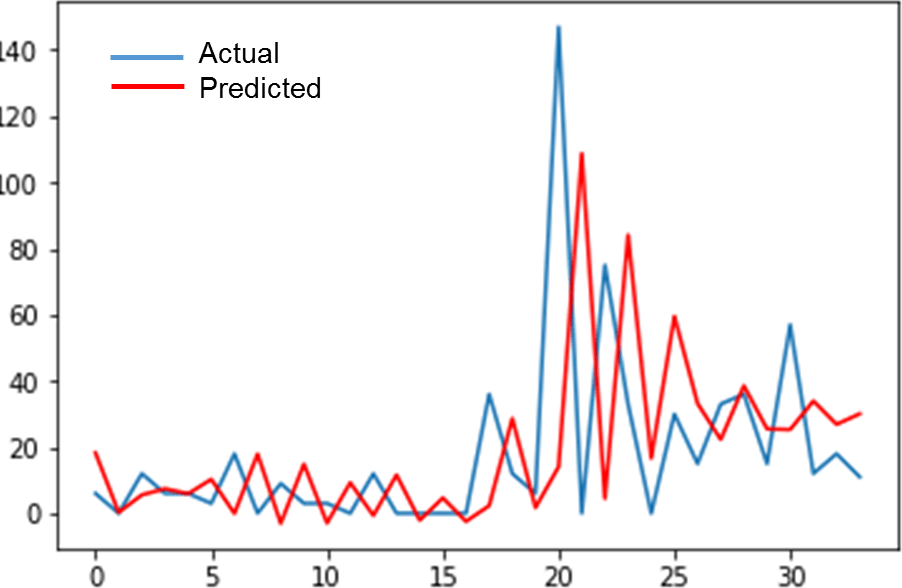

GEMBO Precare collects failure data and uses machine learning to construct models that can accurately predict when a failure has the highest probability of happening. An example is shown below.

OEE

Just as predictive maintenance is important to optimize equipment availability and to eliminate unnecessary scheduled downtime, so is OEE. OEE is an important KPI and tool to discover events and factors that adversely affect equipment effectiveness and customer satisfaction.

OEE is expressed as OEE = availability x performance x quality. Each of these components is measured as follows:

Availability; measured in terms of the amount of time the equipment is generating power in a specified time interval.

Performance; measured in terms of the rate at which the equipment is producing power, i.e., measured in KW hour, or the amount of energy produced per hour.

Quality; measured in terms of the total power in KW produced within a specified time interval. This includes any down time experienced within the specified interval.

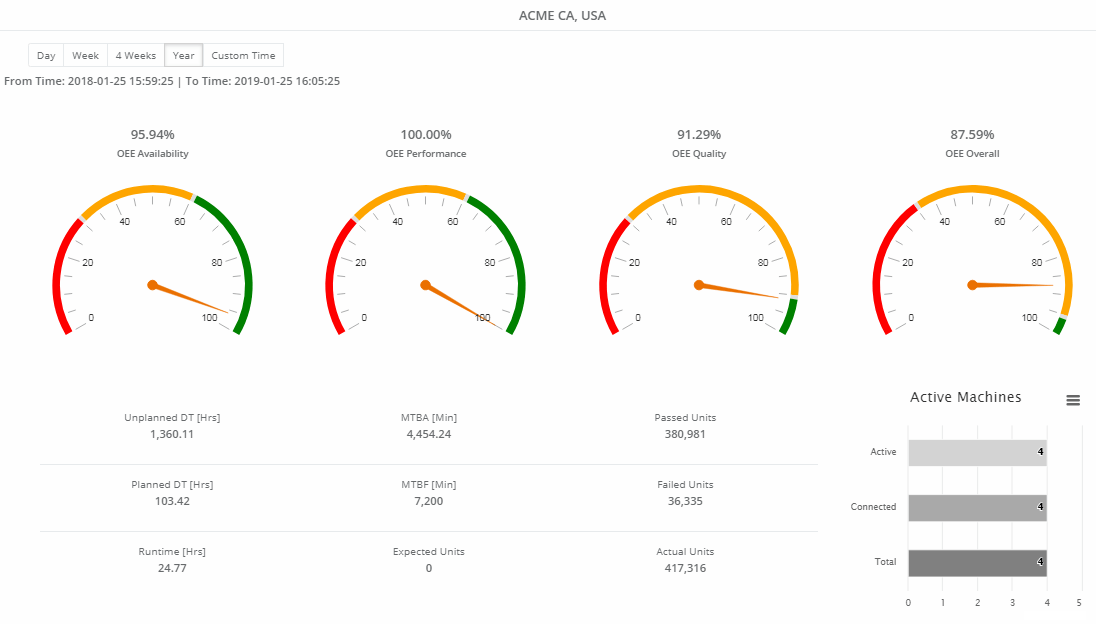

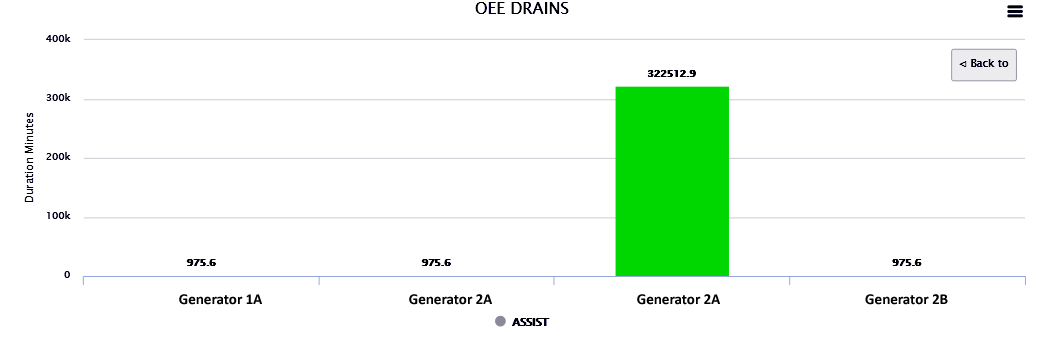

GEMBO Precare not only collects all data necessary to calculate availability, performance, quality and OEE, but drills down to the cause(s) of diminished OEE. An example is shown below for an installation consisting of two buildings, each with two power generator. The GEMBO Precare Rule Engine allows actions to be automatically executed as a result of one or more conditions met simultaneously by one or more monitored signals.

At the top level the OEE KPIs are shown for both buildings, i.e., for both generators combined. Each OEE KPI lists also the details. For instance, for the Availability KPI the hours of unplanned, planned and total run time are shown.

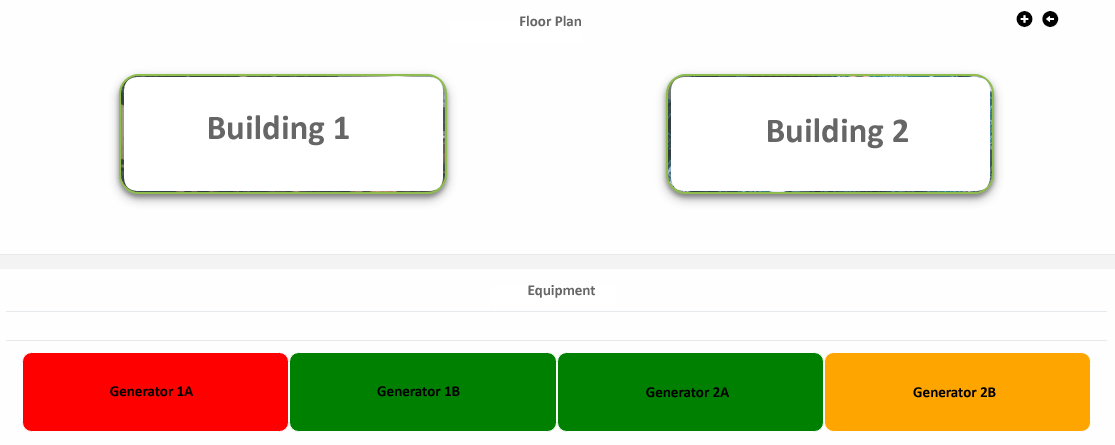

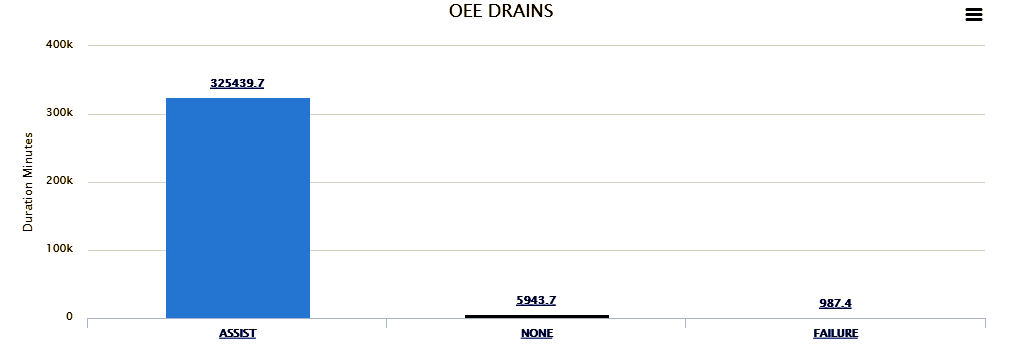

Since the number of unplanned downtime hours is relatively high over the 1 year period selected, the next step is to find out which generator is experiencing high levels of unplanned downtime. Examining the floor plan shows that generator 1A at building 1 is in the red zone currently, experiencing a failure. Generators 1B and 2A are operating normally and generator 2B is experiencing some form of assistive action.

However, this doesn’t necessarily mean that this generator is the cause of the low availability, since the above shows only current status. At the same time the bar graph below shows that the main reason for the downtime is due to number of assist hours.

Clicking on the assist bar shows that the building 2 generator 2A contributes to nearly 100% of the assist hours.

.

GEMBO PRECARE Agents

GEMBO Precare deploys agents which can talk directly to equipment controllers over a host of different physical interfaces and protocols. The key agent features are listed below:

- Real-time data acquisition. GEMBO Precare agents collect any equipment vital data in real-time for overall equipment health analysis and trends.

- Any equipment vitals. Whichever is needed to be monitored, including abnormal power supply voltage fluctuations, unusual noise, abnormal vibrations caused by rotating parts, fuel leakages, etc.

- Any connectivity. Equipment vitals may be collected through sensors on GEMBO Precare agent hardware, from the equipment’s own programmable logic controllers or through a combination of both.

- Low latency. GEMBO Precare agents run on microprocessors which reside in the same location as the equipment, performing on the spot anomaly detection, complex event processing and other latency-sensitive tasks.

- Automated Actions & Complex Event Processing. GEMBO Precare Rule Engine allows actions to be automatically executed as a result of one or more conditions met simultaneously by one or more monitored signals.

- Machine learning. GEMBO Precare agents stream data to the GEMBO Precare cloud platform, where machine learning models are trained for predictive maintenance.

- Dashboards. The GEMBO Precare cloud platform compiles and presents comprehensive KPIs in user-friendly dashboards side by side with equipment status, alarms and graphs, as well as comprehensive reports. KPIs include OEE, availability, performance, quality, MTBF and MTBA, with traceability of problem areas.

- Flexible hosting options. GEMBO Precare can be hosted on your choice of private, public or hybrid cloud.

Conclusions

GEMBO Precare has a set of powerful data acquisition, analytics, predictive and OEE tools for industrial and commercial power generator. GEMBO Precare gathers, analyzes and presents critical and actionable data plus key performance indicators (KPIs) before a system, subsystem or component reaches its breaking point. In addition GEMBO Precare collects important data which can significantly reduce maintenance and repair time, as well as truck rolls. Power generator OEMs and service partners using GEMBO Precare have a set of powerful tools at their fingertips to minimize OpEx and boost customer satisfaction.

GEMBO ( www.gembo.co ) has a SaaS Industrial IOT Platform which provides enterprises and users with mission critical data, insights and decision making tools enabling cost reduction and revenue growth through optimization via the use of IoT, Artificial Intelligence and Machine Learning. Farm Operator Intro A large-scale solar farm operator, managing a 50 MW solar farm with significant investments in infrastructure. The solar farm has a current efficiency of 24% and a target of increasing this efficiency over time. The farm operates in an area where electricity prices are approximately $32 per MWh, and it has a large operational budget dedicated to maintaining its equipment. GEM has deployed the Precare cloud, predictive maintenance and solar power prediction Package, on the customers Data, extracted from the solar farm's SCADA system. Problem Due to the complexity of solar equipment and environmental factors, the customer has faced a gradual decline in efficiency, dropping from 26% to 24% over the past few years. As a result, the farm's revenue has been impacted by lower power output, and operational expenses have been steadily increasing. Furthermore, the lack of predictive maintenance (PdM) has led to frequent downtime and unplanned maintenance, further increasing the inefficiencies. The farm owner reached out for a solution that could improve operational efficiency, reduce costs, and enhance overall power production by using predictive analytics to forecast and mitigate potential issues before they occur. Solution After evaluating the farm’s needs and existing system, GEM’s Predictive Maintenance (PdM) and Solar Power Prediction packages were discussed and found as the right fit. This solution was implemented through GEM’s Precare analytics platform, which helps monitor and predict performance, detect faults early, and optimize maintenance schedules. The key components of GEM’s solution included: Real-time Monitoring: Continuous monitoring of solar inverters, panels, and environmental conditions. Predictive Maintenance: Advanced machine learning models to predict the likelihood of system failures and performance degradation. Power Output Forecasting: Predictive analytics to model expected energy production based on historical data and real-time inputs, leading to more accurate forecasting and optimizing grid management. Results After deploying GEM’s predictive maintenance and power optimization system, GEM provided the customer a calculation of a 3 year business analysis Financial Benefits: Revenue Increase: The system’s efficiency would increase by an additional $864,320 in revenue over 3 years due to the increased power output from the higher efficiency (25% vs. 24%). OPEX Reduction: Predictive maintenance would reduce the monthly operational expenses by 3%, leading to OPEX savings of $78,810 over the 3-year period. Net Benefits: The customer will realize a total net benefit of $758,130 after deducting the initial system cost and subscription fees. ROI: The ROI of 658.13% was computed from the net benefits of $758,130 after accounting for system cost investments.

SELF SERVICE DATA STUDIO CASE STUDY This case study showcases GEMBO, a leader in SaaS Industrial IoT Platforms, enhancing a global manufacturer's operations by deploying its Precare Data Studio BI product across 70 machines. The solution, focused on self-service data management and analytics, resulted in significant manpower savings, improved self-service efficiency, and automated analytics distribution. Unique to GEMBO Precare is its ability to deploy independent sensors, connecting any machine to its cloud, thereby offering predictive maintenance and operational insights without substantial capital expenditure, distinguishing it from other market solutions.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a multi $B Tier one manufacturer, with multiple factories around the globe. Manufacturing lines vary between electronic manufacturing to semiconductor, serving a variety of markets including Automotive, Networking, Industrial, Audio and Gaming. GEM has deployed Precare Cloud , Precare Edge , OEE Availability and predictive analytics Package . Its footprint grew from a few machines to over 90 machines in a few of their factories. Problem The customer has been utilizing OEE Availability analytics to identify machines with low availability and assigning them to responsible technicians. The customer's management team has been overwhelmed with emails from technicians providing status updates on the machines after they have taken corrective actions. The customer intends to streamline the process of monitoring machine status from the receipt of OEE Availability status to the resolution of availability issues, enabling the machines to operate efficiently based on established availability KPIs. The customer has provided the following workflow to illustrate their requirements.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a Tier 1 multi-billion dollar global manufacturing leader in the power, discrete semiconductor, and passive electronic components (PES) space. GEMBO has deployed a suite of innovative, cloud-based solutions to the customer, including Precare Cloud, Precare Edge, OEE Availability, Performance, and Quality packages. These solutions have been deployed to 70 machines across two factory floors, and the customer intends to scale the deployment across their entire Asia-Pacific footprint. Problem The customer's equipment engineering team has been managing the productivity of their machines through manual Excel reports. These reports are prepared by machine operators, checked and consolidated by supervisors, and then reported to management by factory floor managers. The customer needs to minimize or eliminate these manual reports to improve the accuracy of the reports and save on manpower costs. The following are examples of manual reports that the customer needs to eliminate: 1. Calculation of the share of subcategories of Performance and Quality 2. Calculation of the percentage of Planned Downtime to Total Run Time 3. Graphical presentation of OEE Availability with Time Frame These reports are time-consuming and error-prone. They also require a significant amount of manpower to create and maintain. By eliminating these manual reports, the customer can improve the accuracy of their productivity data and save on manpower costs. Solution After a technical discussion with the customer, GEM integrated the manual Excel reports into the OEE analytics framework. The team then implemented the following process: Define the customer requirements Gather the excel reports Create an output image showing changes in the analytics Define data to be collected Collect data from the customers Collect the data from customer Validate the completeness of the data based on the requirements Collect missing data Confirm with customer if all data are accurate and structured properly based on their requirements Prepare the design Overview Customer Requirements Use Case System Diagram Code Diagram Review and approval of the design Testing on Developer Environment Deployment to Production Customer acceptance Results The migration of previously manually prepared OEE reports to a digital format using OEE Analytics resulted in the following benefits: 100% savings on manpower costs, as the reports are now generated automatically and do not require manual input. 100% accuracy, as the data is collected directly from the machines and is not subject to human error. 100% time savings for management, as they no longer need to spend time reviewing and validating the reports. Improved decision-making, as the Operations Group can now access real-time data and insights to make better decisions. Increased efficiency, as the Operations Group can now focus on core tasks and not on data entry and reporting. Conclusions GEMBO Precare has a set of powerful data acquisition, analytics, predictive and OEE tools for manufacturing equipment. GEMBO Precare compiles critical KPIs that can be used to easily trace back which machine or machine subsystem is responsible for a low KPI score. GEMBO Precare is also able to make predictions at equal or better than humanly possible for machine maintenance to be scheduled before a failure occurs. But most importantly, unlike other market solutions, GEMBO Precare is able to deploy its own sensors independently from any machine controller and fully connect any machine data island to the GEMBO Precare Cloud at a fraction of the cost of a new machine; hence, saving manufacturers from having to make large and risky CAPEX and OPEX investments for new machines. Contact Us Visit us at www.gembo.co or contact us via email at sales@gembo.co