Solar Predictive maintenance & power Business Study

GEMBO (www.gembo.co) has a SaaS Industrial IOT Platform which provides enterprises and users with mission critical data, insights and decision making tools enabling cost reduction and revenue growth through optimization via the use of IoT, Artificial Intelligence and Machine Learning.

Farm Operator Intro

A large-scale solar farm operator, managing a 50 MW solar farm with significant investments in infrastructure. The solar farm has a current efficiency of 24% and a target of increasing this efficiency over time. The farm operates in an area where electricity prices are approximately $32 per MWh, and it has a large operational budget dedicated to maintaining its equipment.

GEM has deployed the Precare cloud, predictive maintenance and solar power prediction Package, on the customers Data, extracted from the solar farm's SCADA system.

Problem

Due to the complexity of solar equipment and environmental factors, the customer has faced a gradual decline in efficiency, dropping from 26% to 24% over the past few years. As a result, the farm's revenue has been impacted by lower power output, and operational expenses have been steadily increasing. Furthermore, the lack of predictive maintenance (PdM) has led to frequent downtime and unplanned maintenance, further increasing the inefficiencies.

The farm owner reached out for a solution that could improve operational efficiency, reduce costs, and enhance overall power production by using predictive analytics to forecast and mitigate potential issues before they occur.

Solution

After evaluating the farm’s needs and existing system, GEM’s Predictive Maintenance (PdM) and Solar Power Prediction packages were discussed and found as the right fit. This solution was implemented through GEM’s Precare analytics platform, which helps monitor and predict performance, detect faults early, and optimize maintenance schedules.

The key components of GEM’s solution included:

- Real-time Monitoring: Continuous monitoring of solar inverters, panels, and environmental conditions.

- Predictive Maintenance: Advanced machine learning models to predict the likelihood of system failures and performance degradation.

- Power Output Forecasting: Predictive analytics to model expected energy production based on historical data and real-time inputs, leading to more accurate forecasting and optimizing grid management.

Results

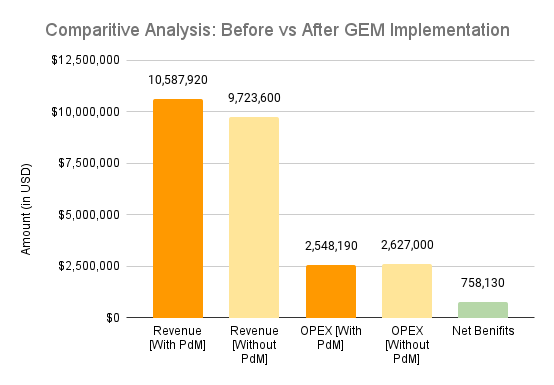

After deploying GEM’s predictive maintenance and power optimization system, GEM provided the customer a calculation of a 3 year business analysis

Financial Benefits:

- Revenue Increase: The system’s efficiency would increase by an additional $864,320 in revenue over 3 years due to the increased power output from the higher efficiency (25% vs. 24%).

- OPEX Reduction: Predictive maintenance would reduce the monthly operational expenses by 3%, leading to OPEX savings of $78,810 over the 3-year period.

- Net Benefits: The customer will realize a total net benefit of $758,130 after deducting the initial system cost and subscription fees.

- ROI: The ROI of 658.13% was computed from the net benefits of $758,130 after accounting for system cost investments.

Figure 1: Comparative Analysis - Before vs After GEM Implementation

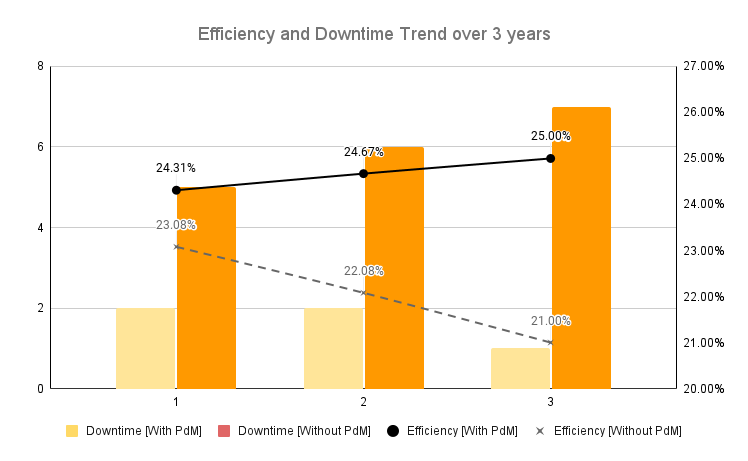

Operational Benefits:

- Increased Efficiency: The system will help increase the solar farm's efficiency by 1% over the 3 years, avoiding the anticipated 3% decline.

- Reduced Downtime: By predicting failures before they occurred, GEM’s PdM system will minimize unexpected downtime and reduce the need for costly emergency repairs.

- Optimized Maintenance: The predictive maintenance feature will enable the customer to perform maintenance only when necessary, reducing the frequency of reactive maintenance and labor costs.

Figure 2: Comparative Analysis - Efficiency and Downtime over 3 years

Conclusion

By integrating GEM's Precare Platform, and applying Renewable Energy Predictive Maintenance and Power Prediction packages, the customer will see not only increase in operational efficiency but also experienced significant financial gains. The combination of proactive fault detection, predictive power forecasting, and optimized maintenance schedules enabled the customer to achieve higher energy production while reducing unnecessary costs.

This writeup highlights how predictive analytics can have a transformative impact on solar farm operations, ensuring long-term profitability and sustainability.

The 658.13% ROI demonstrates the clear value of adopting advanced predictive maintenance in the solar energy industry, showcasing both operational and financial improvements.