Human Operator-in-the-loop OEE

Integrating the Human Factor into Cyber‐Physical Systems

Introduction

Although there are many parts of a factory that contribute to the overall effectiveness of a manufacturing operation, there is no doubt that what happens on the production floor greatly impacts overall effectiveness. Although control and operation of machines in a modern manufacturing operation is highly automated, many such operations rely on a mix of automation and manual operation for aspects that still require operator attention and intervention. Therefore, when measuring equipment OEE (overall equipment effectiveness) from availability, performance and quality, it is not only logical, but necessary to consider the operator as part of the machine.

As such the Cyber-Physical System (CPS) or Digital Twin representation of the equipment must include the human-operator-in-the-loop (HOITL) so that operator data is included as part of the automated collection of data for the entire machine. The challenge is to do this in an unobtrusive fashion, so that the operator is not hampered in any way when interacting with the equipment. Therefore, use of a wearable device requires transmitting operator data wirelessly. An additional requirement is that the solution must be cost-effective.

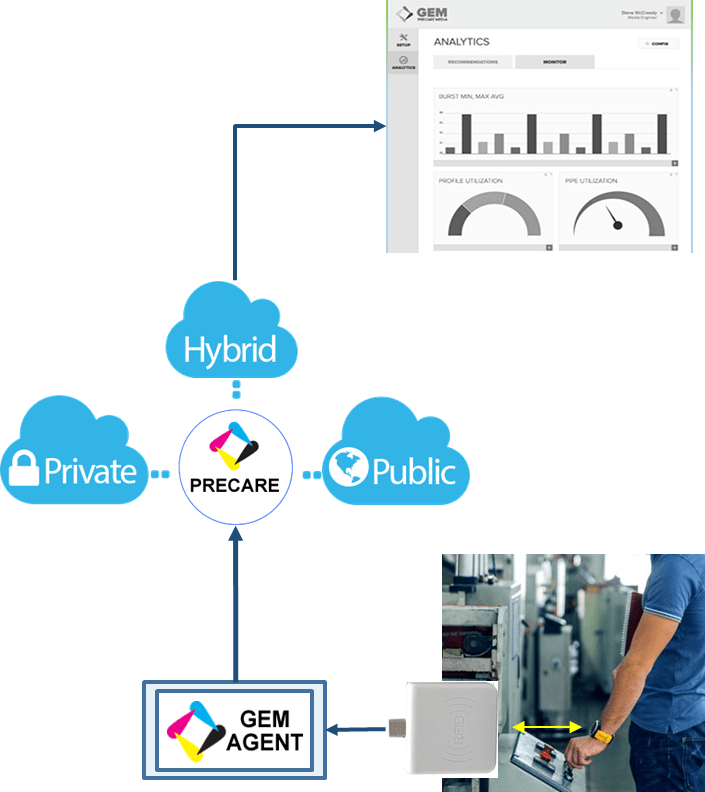

RFID was designed to meet all these three requirements. In this white paper we explore the use of this technology with GEMBO Precare agents that turn any machine into a CPS by streaming data in real-time to the GEMBO Precare Industry 4.0 IIoT platform.

RFID Overview

Industrial and commercial use power generators are complex systems, which are required to operate reliably without interruption and to be available whenever the need arises for backup power. Like with any complex system any number of things can go wrong and will go wrong, no matter the level of planning and preparation. The challenge is therefore to minimize the financial, operational and psychological cost of any malfunction or suboptimal functioning of the system. The following equipment related events negatively impact operational cost and customer satisfaction:

- Equipment breakdown.

- Equipment downtime, regardless of maintenance, repair, out of fuel or other reasons.

- Reduced power output.

What if you could minimize the probability of any of these events and hence reap the fruits of reduced OpEx and increased customer satisfaction?

The GEMBO PRECARE Solution

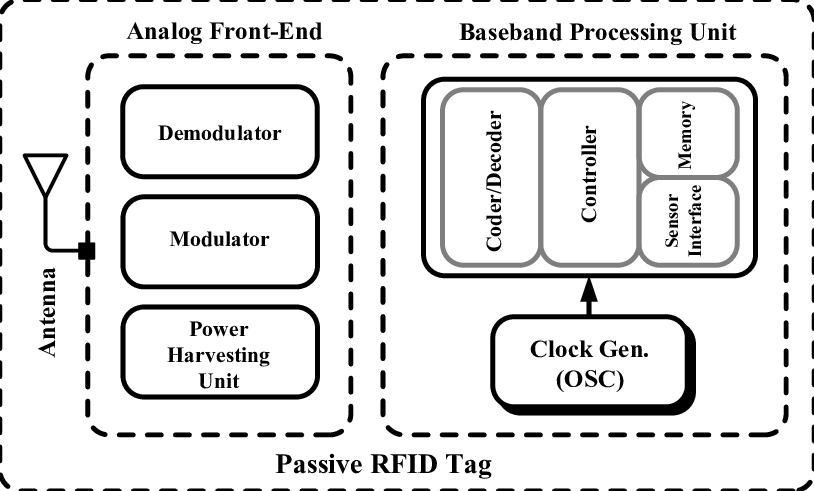

RFID is an acronym for Radio Frequency IDentification. It is intended as a low power means of tagging animate and inanimate objects for identification via a wireless reader. Information about the object is stored in an RFID tag’s on-board Flash memory. Based on how the tag is powered, RFID tags are classified in two main categories:

- Passive RFID tags

- Active RFID tags.

- Rx/Tx antenna;

- Modem (modulator/demodulator);

- Codec (encoder/decoder);

- Logic control circuit;

- Memory;

- RF Energy harvester for passive tags, or battery for active tags.

The main standards bodies for RFID are:

- ISO/IEC;

- IEEE;

- GS1/EPCglobal.

Each country is responsible for defining its own regulations for the use of radio devices, including RFID. The regulations most commonly used are:

- The United States of America Federal Communication Commission (FCC);

- The European Conference of Postal and Telecommunications Administrations (CEPT) through its European Telecommunications Standards Institute (ETSI).

RFID standards cover short-range (Prox Card), near-range (NFC, MIFARE), mid-range (RAIN) and long-range (ISO 18000-7 RFID). Short and near-range RFID don’t require an integrated power source, since it harvests power from the energy transmitted wirelessly by the reader. However, it restricts operator freedom since it requires the operator to bring the tag very close to the reader.

Long-range RFID allows the operator total freedom, but has the drawback that a power source, such as a battery, is required for the tag. Mid-range RFID combines the advantages of long-range and near-range RFID. Actual range is largely determined by the transmission power of the reader.

The following table summarizes the important features of the four RFID types side-by-side

| Attribute | Prox Card | MIFARE/NFC | RAIN RFID | 18000-7 Active RFID |

|---|---|---|---|---|

| Radio Frequency | 125KHz/134.2KHz | 13.56MHz | 890-960MHz | 433MHz |

| Range* | < 100mm | <1000mm | <2.1m | >700m |

| Range* | < 100mm | <1000mm | <2.1m | >700m |

| Power source | Passive: RF coupling Active: battery | Passive: RF coupling Active: battery | Passive: RF coupling Active: battery | Active: Battery |

*) Actual range depends on the transmission power of the reader in case of passive RFID.

The GEMBO Solution

Conclusions

GEMBO Precare supports inclusion of human-in-the-loop in the CPS representation of machines, so that events that negatively affect OEE can be analyzed in full context that includes the operator. Use of passive, medium-range RFID tags provide freedom of movement for the operator and are maintenance free since they don’t require batteries. Using the tag’s relative signal strength combined with multiple readers for relatively large machines is used to determine approximate position of the operator relative to the machine. Therefore, including the human operator in the CPS representation of the equipment allows manufacturers to not only optimize OEE for machine-specific parameters, but also for operator-specific factors.

GEMBO’s HOITL extension of CPS representations of manufacturing equipment makes use of mid-range passive RFID tags in combination with one or more readers positioned strategically relative to the machine. The readers are connected to a GEMBO agent which uses reader location and tag RSS to compute the operator’s position relative to the machine.

When combined with events that impact OEE, such as unplanned down-time events, unintended drops in the machine’s throughput, unexpected increase of rejected product quantities, etc., a more complete understanding of loss of OEE is gained and therefore root cause analyses can be more accurate.

GEMBO agents can perform real-time processing and interpretation of the CPS data and take action immediately at the edge. Simultaneously the agents stream the data to the GEMBO Precare cloud platform where data from all agents can be combined for the compilation of factory-wide KPIs, big data analytics for the detection of more general patterns for instance, and for accelerating training and validation of machine learning algorithms.

GEMBO ( www.gembo.co ) has a SaaS Industrial IOT Platform which provides enterprises and users with mission critical data, insights and decision making tools enabling cost reduction and revenue growth through optimization via the use of IoT, Artificial Intelligence and Machine Learning. Farm Operator Intro A large-scale solar farm operator, managing a 50 MW solar farm with significant investments in infrastructure. The solar farm has a current efficiency of 24% and a target of increasing this efficiency over time. The farm operates in an area where electricity prices are approximately $32 per MWh, and it has a large operational budget dedicated to maintaining its equipment. GEM has deployed the Precare cloud, predictive maintenance and solar power prediction Package, on the customers Data, extracted from the solar farm's SCADA system. Problem Due to the complexity of solar equipment and environmental factors, the customer has faced a gradual decline in efficiency, dropping from 26% to 24% over the past few years. As a result, the farm's revenue has been impacted by lower power output, and operational expenses have been steadily increasing. Furthermore, the lack of predictive maintenance (PdM) has led to frequent downtime and unplanned maintenance, further increasing the inefficiencies. The farm owner reached out for a solution that could improve operational efficiency, reduce costs, and enhance overall power production by using predictive analytics to forecast and mitigate potential issues before they occur. Solution After evaluating the farm’s needs and existing system, GEM’s Predictive Maintenance (PdM) and Solar Power Prediction packages were discussed and found as the right fit. This solution was implemented through GEM’s Precare analytics platform, which helps monitor and predict performance, detect faults early, and optimize maintenance schedules. The key components of GEM’s solution included: Real-time Monitoring: Continuous monitoring of solar inverters, panels, and environmental conditions. Predictive Maintenance: Advanced machine learning models to predict the likelihood of system failures and performance degradation. Power Output Forecasting: Predictive analytics to model expected energy production based on historical data and real-time inputs, leading to more accurate forecasting and optimizing grid management. Results After deploying GEM’s predictive maintenance and power optimization system, GEM provided the customer a calculation of a 3 year business analysis Financial Benefits: Revenue Increase: The system’s efficiency would increase by an additional $864,320 in revenue over 3 years due to the increased power output from the higher efficiency (25% vs. 24%). OPEX Reduction: Predictive maintenance would reduce the monthly operational expenses by 3%, leading to OPEX savings of $78,810 over the 3-year period. Net Benefits: The customer will realize a total net benefit of $758,130 after deducting the initial system cost and subscription fees. ROI: The ROI of 658.13% was computed from the net benefits of $758,130 after accounting for system cost investments.

SELF SERVICE DATA STUDIO CASE STUDY This case study showcases GEMBO, a leader in SaaS Industrial IoT Platforms, enhancing a global manufacturer's operations by deploying its Precare Data Studio BI product across 70 machines. The solution, focused on self-service data management and analytics, resulted in significant manpower savings, improved self-service efficiency, and automated analytics distribution. Unique to GEMBO Precare is its ability to deploy independent sensors, connecting any machine to its cloud, thereby offering predictive maintenance and operational insights without substantial capital expenditure, distinguishing it from other market solutions.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a multi $B Tier one manufacturer, with multiple factories around the globe. Manufacturing lines vary between electronic manufacturing to semiconductor, serving a variety of markets including Automotive, Networking, Industrial, Audio and Gaming. GEM has deployed Precare Cloud , Precare Edge , OEE Availability and predictive analytics Package . Its footprint grew from a few machines to over 90 machines in a few of their factories. Problem The customer has been utilizing OEE Availability analytics to identify machines with low availability and assigning them to responsible technicians. The customer's management team has been overwhelmed with emails from technicians providing status updates on the machines after they have taken corrective actions. The customer intends to streamline the process of monitoring machine status from the receipt of OEE Availability status to the resolution of availability issues, enabling the machines to operate efficiently based on established availability KPIs. The customer has provided the following workflow to illustrate their requirements.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a Tier 1 multi-billion dollar global manufacturing leader in the power, discrete semiconductor, and passive electronic components (PES) space. GEMBO has deployed a suite of innovative, cloud-based solutions to the customer, including Precare Cloud, Precare Edge, OEE Availability, Performance, and Quality packages. These solutions have been deployed to 70 machines across two factory floors, and the customer intends to scale the deployment across their entire Asia-Pacific footprint. Problem The customer's equipment engineering team has been managing the productivity of their machines through manual Excel reports. These reports are prepared by machine operators, checked and consolidated by supervisors, and then reported to management by factory floor managers. The customer needs to minimize or eliminate these manual reports to improve the accuracy of the reports and save on manpower costs. The following are examples of manual reports that the customer needs to eliminate: 1. Calculation of the share of subcategories of Performance and Quality 2. Calculation of the percentage of Planned Downtime to Total Run Time 3. Graphical presentation of OEE Availability with Time Frame These reports are time-consuming and error-prone. They also require a significant amount of manpower to create and maintain. By eliminating these manual reports, the customer can improve the accuracy of their productivity data and save on manpower costs. Solution After a technical discussion with the customer, GEM integrated the manual Excel reports into the OEE analytics framework. The team then implemented the following process: Define the customer requirements Gather the excel reports Create an output image showing changes in the analytics Define data to be collected Collect data from the customers Collect the data from customer Validate the completeness of the data based on the requirements Collect missing data Confirm with customer if all data are accurate and structured properly based on their requirements Prepare the design Overview Customer Requirements Use Case System Diagram Code Diagram Review and approval of the design Testing on Developer Environment Deployment to Production Customer acceptance Results The migration of previously manually prepared OEE reports to a digital format using OEE Analytics resulted in the following benefits: 100% savings on manpower costs, as the reports are now generated automatically and do not require manual input. 100% accuracy, as the data is collected directly from the machines and is not subject to human error. 100% time savings for management, as they no longer need to spend time reviewing and validating the reports. Improved decision-making, as the Operations Group can now access real-time data and insights to make better decisions. Increased efficiency, as the Operations Group can now focus on core tasks and not on data entry and reporting. Conclusions GEMBO Precare has a set of powerful data acquisition, analytics, predictive and OEE tools for manufacturing equipment. GEMBO Precare compiles critical KPIs that can be used to easily trace back which machine or machine subsystem is responsible for a low KPI score. GEMBO Precare is also able to make predictions at equal or better than humanly possible for machine maintenance to be scheduled before a failure occurs. But most importantly, unlike other market solutions, GEMBO Precare is able to deploy its own sensors independently from any machine controller and fully connect any machine data island to the GEMBO Precare Cloud at a fraction of the cost of a new machine; hence, saving manufacturers from having to make large and risky CAPEX and OPEX investments for new machines. Contact Us Visit us at www.gembo.co or contact us via email at sales@gembo.co