Industry 4.0 Benefits Without Industry 4.0 Costs

The Customer

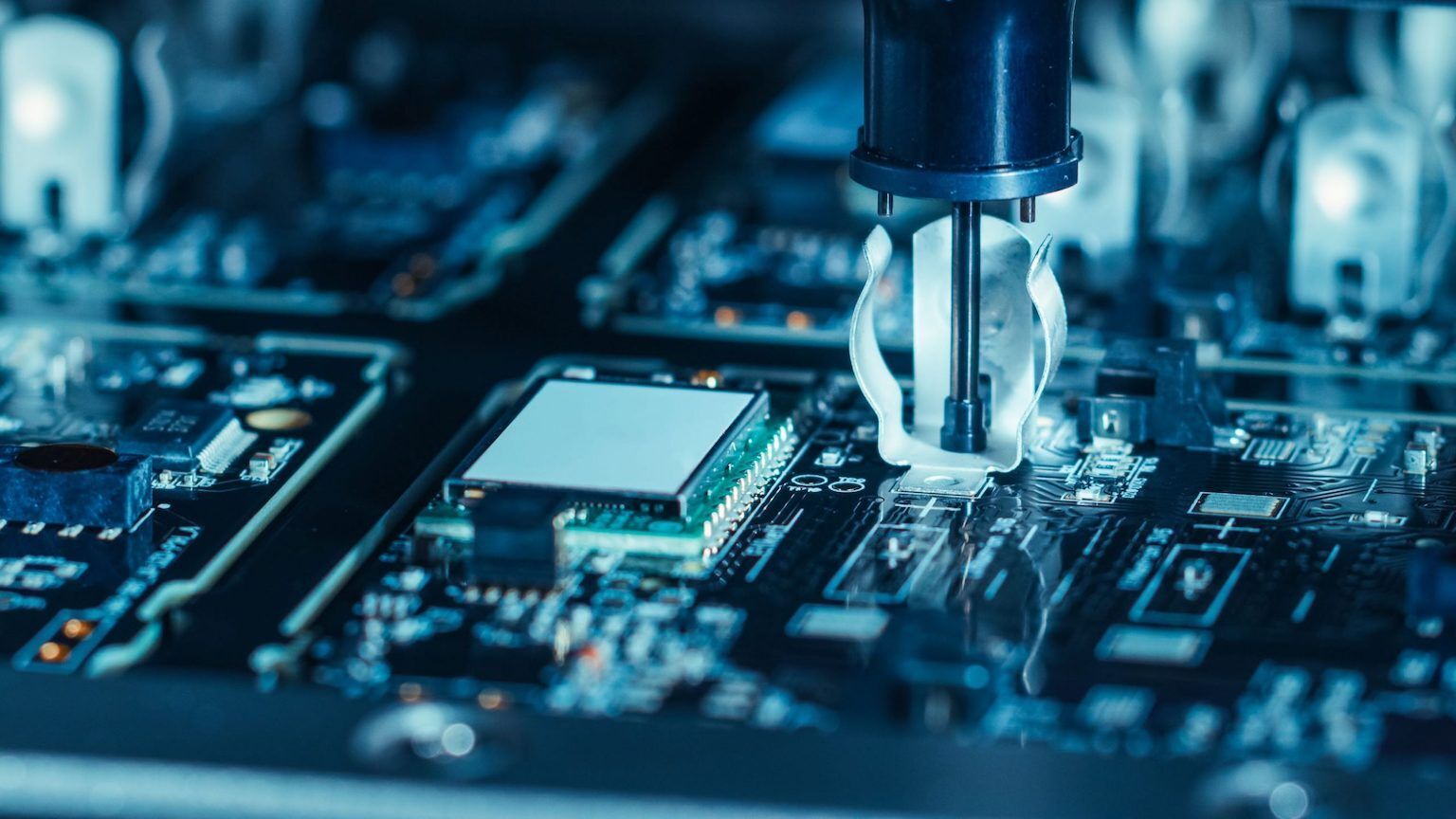

Semiconductor manufacturers are constantly under pressure to squeeze the most out of their capital and operational expenses, while at the same time facing tremendous pressure in a global market from their customers to deliver the highest quality within the shortest lead time.

Whereas COOs are held responsible for CapEx, OpEx and overall performance across all manufacturing sites and business units, VPs at each business unit are responsible for CapEx, OpEx and overall performance of their own business unit, while factory floor directors are responsible for manufacturing operations at their plants to run as efficiently and productive as possible. In concrete terms this means minimizing unplanned machine downtime and maximizing machine throughput, while keeping manufacturing quality high; or in industry parlance, maximizing OEE (Overall Equipment Effectiveness).

The Challenge

Maximizing OEE in semiconductor manufacturing is a non-trivial task. The manufacturing workflow involves multiple stages; each handled by machines specialized for the particular operations involved in a stage. It is not uncommon to find machines from different OEMs handling the same or different tasks on the manufacturing floor, where some machines may be controlled by older generation Operating Systems (some with none), PLCs (Programmable Logic Controllers) that don’t have the ability to provide machine status, performance, quality and availability data in real-time to spot trends to predict when maintenance needs to be scheduled and optimize equipment effectiveness.

This situation includes having no access at all to data for analysis and having access, but having to import the data in batch mode, missing crucial data. In addition, where the data is available, it is often in formats that differ from machine to machine, and more often than not, in formats incompatible with prevalent IIoT formats, such as JSON, XML, etc. To top it all off, a plethora of different communication protocols, ranging from SECS/GEMBO , SCADA and RS232/485 to various flavors of Industrial Ethernet compound the problem of access to data for analytics even further.

As a consequence all stakeholders, from factory floor to corporate office, don’t have access to crucial data to help them make well-informed decisions towards OEE optimization in order to meet the end goal of growing bottom line revenue and market share.

The Solution

Industry 4.0 augments Industry 3.0 process control automation systems with big data and big data analytics. At one end of the Industry 4.0 spectrum this means real-time machine data access, while at the other end of the spectrum this means bridging the chasm between operational technology systems on the factory floor and information technology systems in the back-office.

Industry 4.0 creates a digital twin or cyber physical system (CPS) of each machine on the factory floor. These digital twins allow all stakeholders to take advantage of the full Industry 4.0 spectrum of big data analytics opportunities. A 2018 PwC survey of the electronics manufacturing industry estimates that 45% of manufacturers are already deploying or are in process of deploying Industry 4.0 systems, while another 32% is planning to deploy Industry 4.0 systems within the next 5 years.

The GEMBO PRECARE platform is able to offer semiconductor manufacturers a complete Industry 4.0 upgrade which is tailored to their specific needs, with all the benefits of big data analytics to optimize OEE, but without the cost of overhauling their existing machinery. The highlights of this solution are summarized below.

The Results

By deploying GEMBO PRECARE for Industry 4.0, semiconductor manufacturers gain instant access to all machine data and OEE analytics without having to do a complete overhaul of their existing OT infrastructure. As such they realize significant savings in migrating to Industry 4.0 and gain valuable insight in every machine’s availability, performance, quality, MTBF, MTBA, and other KPIs to be able to undertake necessary actions towards process flow and machine performance optimization, as well as when exactly to schedule maintenance. The overall result is that manufacturers are able to realize increases in OEE as much as 30-40%, increasing OEE scores to as high as 90%.

Real-time data from any machine

Future proofing any machine

Large library of machines

Any factory floor data store

Machine MTB data

Machine OEE data

Machine data format uniformity

Low-latency edge processing

Robustness

Security

Big data analytics

Uniform data visualization

Hierarchy representation

Powerful rule engine

Range of notification methods

Flexible hosting options

Whether legacy or latest generation, agents obtain critical status and operational data in real-time, instantly creating digital twins and extending machine life cycles

A large and growing digital twin library of supported semiconductor manufacturing machines drastically reduces time-to-deployment

Agents can access any networked factory floor data store, including support for OPC-UA, NFS or other network file systems

Agents collect machine status data for any status category and at any level of detail required by the manufacturer, including failures and assists

Agents collect machine OEE availability, performance and quality data, with availability at any level of detail and quality for any equipment modality required by the manufacturer

Agents transform differing data formats into formats that are uniform across all machines

Agents perform complex event processing and notifications at the edge for minimal latency

Auto-recovery of agent datacom links and data store & forward guarantees maximum robustness and no missing data

Strong security at every connectivity stage, from agent to cloud, and VPN support prevents data and access breaches

Analytics such as OEE, MTBF, MTBA, predictive maintenance, etc. are instantly available at one’s fingertips, for any time period and at any factory hierarchical level

Status and machine performance data is presented in a machine agnostic way, presenting a unified dashboard across different machines and OEMs

OEE, MTB and statuses can be presented at any level, across all factory locations down to a single machine

A flexible, visually programmable rule engine supports complex rules and multiple parameters

Stakeholders get notifications instantly across multiple applications and platforms, including text, email, mobile, etc.

Platform hosting options include private, public and hybrid clouds

GEMBO ( www.gembo.co ) has a SaaS Industrial IOT Platform which provides enterprises and users with mission critical data, insights and decision making tools enabling cost reduction and revenue growth through optimization via the use of IoT, Artificial Intelligence and Machine Learning. Farm Operator Intro A large-scale solar farm operator, managing a 50 MW solar farm with significant investments in infrastructure. The solar farm has a current efficiency of 24% and a target of increasing this efficiency over time. The farm operates in an area where electricity prices are approximately $32 per MWh, and it has a large operational budget dedicated to maintaining its equipment. GEM has deployed the Precare cloud, predictive maintenance and solar power prediction Package, on the customers Data, extracted from the solar farm's SCADA system. Problem Due to the complexity of solar equipment and environmental factors, the customer has faced a gradual decline in efficiency, dropping from 26% to 24% over the past few years. As a result, the farm's revenue has been impacted by lower power output, and operational expenses have been steadily increasing. Furthermore, the lack of predictive maintenance (PdM) has led to frequent downtime and unplanned maintenance, further increasing the inefficiencies. The farm owner reached out for a solution that could improve operational efficiency, reduce costs, and enhance overall power production by using predictive analytics to forecast and mitigate potential issues before they occur. Solution After evaluating the farm’s needs and existing system, GEM’s Predictive Maintenance (PdM) and Solar Power Prediction packages were discussed and found as the right fit. This solution was implemented through GEM’s Precare analytics platform, which helps monitor and predict performance, detect faults early, and optimize maintenance schedules. The key components of GEM’s solution included: Real-time Monitoring: Continuous monitoring of solar inverters, panels, and environmental conditions. Predictive Maintenance: Advanced machine learning models to predict the likelihood of system failures and performance degradation. Power Output Forecasting: Predictive analytics to model expected energy production based on historical data and real-time inputs, leading to more accurate forecasting and optimizing grid management. Results After deploying GEM’s predictive maintenance and power optimization system, GEM provided the customer a calculation of a 3 year business analysis Financial Benefits: Revenue Increase: The system’s efficiency would increase by an additional $864,320 in revenue over 3 years due to the increased power output from the higher efficiency (25% vs. 24%). OPEX Reduction: Predictive maintenance would reduce the monthly operational expenses by 3%, leading to OPEX savings of $78,810 over the 3-year period. Net Benefits: The customer will realize a total net benefit of $758,130 after deducting the initial system cost and subscription fees. ROI: The ROI of 658.13% was computed from the net benefits of $758,130 after accounting for system cost investments.

SELF SERVICE DATA STUDIO CASE STUDY This case study showcases GEMBO, a leader in SaaS Industrial IoT Platforms, enhancing a global manufacturer's operations by deploying its Precare Data Studio BI product across 70 machines. The solution, focused on self-service data management and analytics, resulted in significant manpower savings, improved self-service efficiency, and automated analytics distribution. Unique to GEMBO Precare is its ability to deploy independent sensors, connecting any machine to its cloud, thereby offering predictive maintenance and operational insights without substantial capital expenditure, distinguishing it from other market solutions.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a multi $B Tier one manufacturer, with multiple factories around the globe. Manufacturing lines vary between electronic manufacturing to semiconductor, serving a variety of markets including Automotive, Networking, Industrial, Audio and Gaming. GEM has deployed Precare Cloud , Precare Edge , OEE Availability and predictive analytics Package . Its footprint grew from a few machines to over 90 machines in a few of their factories. Problem The customer has been utilizing OEE Availability analytics to identify machines with low availability and assigning them to responsible technicians. The customer's management team has been overwhelmed with emails from technicians providing status updates on the machines after they have taken corrective actions. The customer intends to streamline the process of monitoring machine status from the receipt of OEE Availability status to the resolution of availability issues, enabling the machines to operate efficiently based on established availability KPIs. The customer has provided the following workflow to illustrate their requirements.

GEMBO ( www.gembo.co ) is a leading innovator in the world of SaaS Industrial IoT Platforms, with a proven track record of delivering cutting-edge solutions that help customers achieve their business goals. The company's platform uses a combination of IoT, machine learning, and AI to provide customers with real-time insights into their operations, enabling them to make better decisions and optimize their performance. GEMBO is committed to continuous innovation, and the company is constantly looking for new ways to use technology to help its customers succeed. Customer Intro The customer is a Tier 1 multi-billion dollar global manufacturing leader in the power, discrete semiconductor, and passive electronic components (PES) space. GEMBO has deployed a suite of innovative, cloud-based solutions to the customer, including Precare Cloud, Precare Edge, OEE Availability, Performance, and Quality packages. These solutions have been deployed to 70 machines across two factory floors, and the customer intends to scale the deployment across their entire Asia-Pacific footprint. Problem The customer's equipment engineering team has been managing the productivity of their machines through manual Excel reports. These reports are prepared by machine operators, checked and consolidated by supervisors, and then reported to management by factory floor managers. The customer needs to minimize or eliminate these manual reports to improve the accuracy of the reports and save on manpower costs. The following are examples of manual reports that the customer needs to eliminate: 1. Calculation of the share of subcategories of Performance and Quality 2. Calculation of the percentage of Planned Downtime to Total Run Time 3. Graphical presentation of OEE Availability with Time Frame These reports are time-consuming and error-prone. They also require a significant amount of manpower to create and maintain. By eliminating these manual reports, the customer can improve the accuracy of their productivity data and save on manpower costs. Solution After a technical discussion with the customer, GEM integrated the manual Excel reports into the OEE analytics framework. The team then implemented the following process: Define the customer requirements Gather the excel reports Create an output image showing changes in the analytics Define data to be collected Collect data from the customers Collect the data from customer Validate the completeness of the data based on the requirements Collect missing data Confirm with customer if all data are accurate and structured properly based on their requirements Prepare the design Overview Customer Requirements Use Case System Diagram Code Diagram Review and approval of the design Testing on Developer Environment Deployment to Production Customer acceptance Results The migration of previously manually prepared OEE reports to a digital format using OEE Analytics resulted in the following benefits: 100% savings on manpower costs, as the reports are now generated automatically and do not require manual input. 100% accuracy, as the data is collected directly from the machines and is not subject to human error. 100% time savings for management, as they no longer need to spend time reviewing and validating the reports. Improved decision-making, as the Operations Group can now access real-time data and insights to make better decisions. Increased efficiency, as the Operations Group can now focus on core tasks and not on data entry and reporting. Conclusions GEMBO Precare has a set of powerful data acquisition, analytics, predictive and OEE tools for manufacturing equipment. GEMBO Precare compiles critical KPIs that can be used to easily trace back which machine or machine subsystem is responsible for a low KPI score. GEMBO Precare is also able to make predictions at equal or better than humanly possible for machine maintenance to be scheduled before a failure occurs. But most importantly, unlike other market solutions, GEMBO Precare is able to deploy its own sensors independently from any machine controller and fully connect any machine data island to the GEMBO Precare Cloud at a fraction of the cost of a new machine; hence, saving manufacturers from having to make large and risky CAPEX and OPEX investments for new machines. Contact Us Visit us at www.gembo.co or contact us via email at sales@gembo.co