CASE STUDY

GEMBO PRECARE INDUSTRY 4.0 COMPLEX EVENT PROCESSING

The GEM PRECARE platform enables manufacturers to seamlessly make the transition to Industry 4.0, while keeping their investments in legacy machines; thus, being able to tap into the potential of real-time access to sensor data in order to improve efficiency, productivity and quality.

Real-time access to process data is made possible through the deployment of sensors and is crucial in process control and monitoring. Complex event processing, or CEP in short, at the edge of the cloud or at the machine itself requires hardware platforms with adequate processing power. GEM Precare supports edge processing of sensor data through the use of powerful GEM Agents.

Another important benefit derived from real-time access to machine performance data is the ability to perform data analytics and to apply machine learning techniques to spot trends which can predict when to schedule maintenance. The benefit of predictive maintenance over planned maintenance is that the former reduces the amount of down-time of the machine, since it’s no longer being serviced at regular intervals regardless of the actual performance or condition of the machine, but only in case of reaching a preset maximum tolerance level, the timing of which can be predicted from trends over time in the data patterns of the machine.Thus, predictive maintenance increases overall equipment effectiveness, or OEE in short.

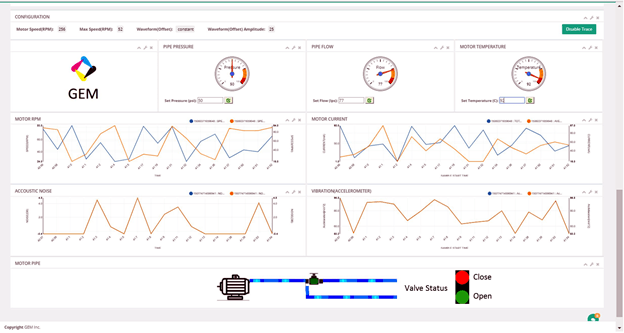

In a motor control example, GEM Agents perform control and CEP at the edge. The GEM PRECARE platform is fed data from all the GEM Agents in the plant, allowing it to present a dashboard for each instance, calculate OEE, MTBF and MTBA for each instance as well as for the entire plant, and analyze the monitored signals to create predictive maintenance models.